| MATERIAL SAFETY DATA SHEET [MSDS] |

| Page: 1 Issued: July 20.2020 |

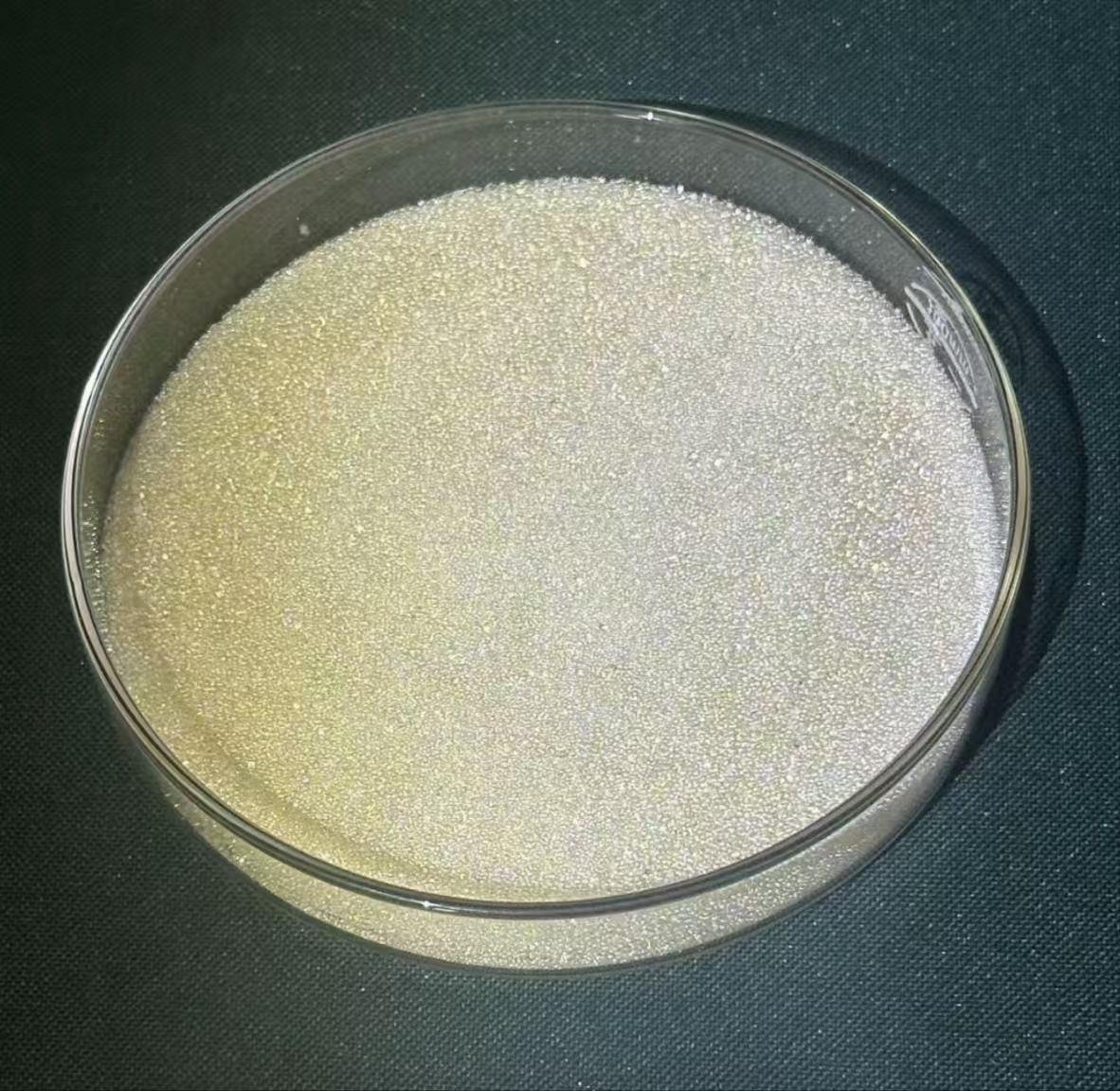

| SECTION 1 CHEMICAL PRODUCT AND COMPANY IDENTIFICATION PRODUCT NAME: Glass Beads CHEMICAL NAME: Glass Beads PRODUCT DESCRIPTION: Transparent small round ball HS Code: 70182000.90 CAS No:13870-30-9 _____________________________________________________________________ CONTACT ADDRESS: |

| 2. COMPOSITION / INFORMATION ON INGREDIENTS Substances by Weight |

| (%): |

| Glass Silicon Dioxide Sodium Oxide Calcium Oxide Magnesium Oxide Potassium Oxide Aluminum Oxide |

| 100.0 |

| SiO2 |

| 72.81% 13.35% 8.74% 1.15% 0.72% 2.62% |

| Na O |

| 2 |

| CaO |

| MgO |

| K O |

| 2 |

| Al O |

| Ferric Oxide |

| Fe2O3 |

| 0.18% |

| 3. HAZARDS IDENTIFICATION |

| As shipped, this product does not pose any health hazard because it does not contain ingredients which are known to cause immediate or serious effects. 4. FIRST AID MEASURES (SYMPTOMS) |

| Skin contact: Eye contact: Ingestion: |

| There may be mild irritation at the site of contact. There may be irritation and redness. No Symptoms. |

| Inhalation: |

| Exposure may cause coughing or wheezing. |

| 4. FIRST AID MEASURES (ACTIONS) |

| Skin contact: Eye contact: |

| Wash immediately with plenty of soap and water. |

| Bathe the eye with running water for at least 15 minutes. Also rinse under the eyelids. If irritation persists, consult a specialist. Wash out mouth with water. Remove to fresh air. |

| Ingestion: Inhalation: |

| 5. |

| FIRE FIGHTING MEAURES |

| Extinguishing Media: Non-Flammable substance, not applicable. Suitable extinguishing media for the surrounding fire should be used. Protection of fire-fighters: Wear self-contained breathing apparatus. Wear protective clothing to prevent contact with skin and eyes. |

|

| MATERIAL SAFETY DATA SHEET [MSDS] |

| Page: 2 |

| 6. |

| ACCIDENTAL RELEASE MEASURES |

| Personal Precautions: Refer to section 8 below for personal protection details. Clean-Up Procedure: Transfer to a suitable container. Material can create slippery conditions underfoot. Avoid creating dust. |

| 7. |

| HANDLING AND STORAGE |

| Handling Requirements: Ensure there is sufficient ventilation of the area. Avoid direct contact with the substance. Avoid the formation or spread of dust in the air. |

| Storage Conditions: |

| Store in cool, well ventilated area. Keep bottles tightly closed. |

| 8. |

| EXPOSURE CONTROLS / PERSONAL PROTECTION |

| Engineering Methods: Respiratory Protection: Hand protection: Eye Protection: Skin Protection: |

| Ensure there is exhaust ventilation of the area. Respiratory protective device with particle filter. Protective gloves. Safety glasses. Ensure eye bath is to hand. Protective clothing. |

| 9. |

| PHYSICAL AND CHEMICAL PROPERTIES |

| State: |

| Solid Sphere |

| Colour: Odour: |

| White. Odourless. |

| Melting Point/Range°C: Relative Density: |

| Approximately 730°C 2.4-2.6 g/cm3 (20°C) |

| 10. |

| STABILITY AND REACTIVITY |

| The product is stable and non-reactive under normal conditions. This product will react with hydrofluoric, fluorosilicic, and phosphoric acids to produce corrosive gases. Hot, strong alkaline solutions will react with this product also. |

| 11. |

| TOXICOLOGICAL INFORMATION |

| As with any abrasive material, this product is irritating to skin and eyes. May be irritating to respiratory tract. Ingestion (acute/chron-ic) may be irritating to the digestive tract. Irritation is described as reversible inflammation. The potential hazard of solid particles depends on particle size and concentration per cubic metre of air. |

| Particle size: Inhalable (< 100 μm) – when deposited anywhere in the respiratory tract Thoracic (< 25 μ m) – when deposited anywhere within the lung airways and the gas- exchange region Respirable (< 10 μm) – when deposited in the gas-exchange region |

| The following Threshold Limit Values (TLV s) refer to airborne concentrations of constituents in this product (and their effects as described by the ACGIH): |

| 3 |

| PEL – Permissible Exposure Limit (mg/m ) TWA – Time Weighted Average (mg/m3) |

| OSHA ACGIH |

| 3 |

| STEL/C – Short-term Exposure Limit / Ceiling (mg/m ) |

| 12. |

| ECOLOGICAL INFORMATION |

| Mobility: |

| No data available. Persistence and degradability: No data available. Bioaccumulative Potential: No data available. |

| MATERIAL SAFETY DATA SHEET [MSDS] |

| Page: 3 |

| 13. |

| DISPOSAL CONSIDERATIONS |

| Disposal Operations: Disposal of Packaging: NB: |

| Contact waste disposal services. Contact waste disposal services. The users attention is drawn to the possible existence of regional or national regulations regarding disposal. |

| Pickup and reuse clean materials, avoiding dusting situations. Dispose of waste materials only in accordance with applicable federal, state, and local laws and regulations. This product is not hazardous as a waste. Check with local landfills before disposing in trash. Dispose of in closed containers to avoid dusting. |

| 14. |

| TRANSPORTATION INFORMATION |

| DOT Hazard Classification: |

| None Placard Required: None |

| Label Required:use original label including all warnings. When disposing of this material in its pure form use a DOT “Non-Hazardous Waste” label. This material is classified as “non-hazardous” according to U .S. and international shipping regulation. |

| Glass beads is not IMO regulated. |

| 15. REGULATORY INFORMATION |

| Hazard Symbols: Note: |

| No significant hazard. |

| The regulatory information given above only indicates the principal regulations specifically applicable to the product described in the safety data sheet. The user’s attention is drawn to the possible existence of additional provisions which complete these regulations. Refer to all applicable national, international and local regulations or provisions. |

| 16. OTHER INFORMATION Other Information: |

| Complies with Directives (2001/58/EC), (1999/45/EC), (91/155/EEC), (67/548/EEC) as amended and Chemicals (hazard information and packaging for supply) 2002 (CHIP3) Regulation, EH40. |

| Legal Disclaimer: |

| The information contained in this safety Data Sheet is correct to the best of our knowledge, information and belief at the date of its publication. |

| The information given is designed only as guidance for safe handling, use, processing, storage, transportation, disposal and release and it is not to be considered a warranty or quality specification. The information relates only to the specific material designated and may not be valid for such material used in combination with any other materials or in any process unless specified in the text. |